Title: The Making of Down Cotton: Understanding its Origin and Production Process

The making of down cotton is a complex and fascinating process. This article provides a detailed understanding of its origin and production process. From the selection of the finest raw materials to the final product, it explains each step meticulously. The article highlights the importance of understanding the supply chain and how it affects the quality and cost of down cotton. It also discusses the various production methods and how they influence the texture, warmth, and durability of the final product. Through this article, one can gain a deeper appreciation for the skilled craftsmanship and attention to detail that goes into making down cotton.

Down cotton, often known for its softness and warmth, has become a popular material in the clothing and textile industry. But what exactly is down cotton and how is it made? In this article, we delve into the production process and the materials used to create down cotton.

What is Down Cotton?

Down cotton is a type of synthetic fiber that is known for its soft, lightweight, and warm properties. It is often used in jackets, coats, and other clothing items that require insulation and warmth. The name "down cotton" comes from the fact that it feels similar to natural down feathers, but without the use of any animal products. This makes it a sustainable and animal-friendly alternative to real down.

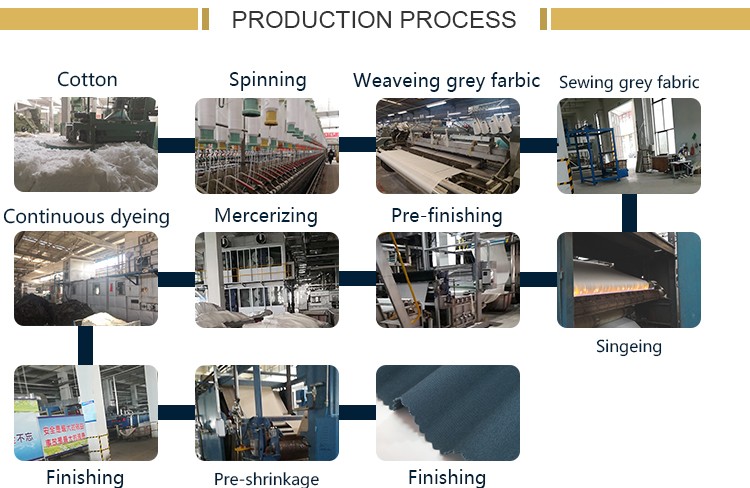

Production Process

The production of down cotton involves several steps. The process starts with the creation of a polymer solution, which is then extruded through small holes to form continuous filaments. These filaments are then cut into shorter fibers, similar to the lengths of natural cotton fibers. These fibers are then spun into yarn, which is then woven or knitted into fabric.

The final step in the production process involves adding a water-resistant coating to the fabric, which makes it more durable and less susceptible to wear and tear. This coating also enhances the insulation properties of the down cotton, providing additional warmth.

Materials Used

The production of down cotton involves the use of several materials. The main material used is polymer, which is a type of plastic material. The most commonly used polymers in the production of down cotton include polyesters and polyamides. These polymers are chosen for their strength, durability, and resistance to wear and tear.

In addition to polymers, the production of down cotton also involves the use of solvents and additives. Solvents are used to dissolve the polymers and create a solution that can be extruded into filaments. Additives are then added to enhance the properties of the down cotton, such as water resistance or insulation.

Finally, the production of down cotton also requires the use of water and energy. The polymer solution needs to be heated and cooled at various stages of the process, and clean water is used for rinsing and cleaning the equipment.

Sustainability Considerations

Down cotton production has come a long way in terms of sustainability. Synthetic fibers, such as those used in down cotton, are often made from recycled materials, reducing the environmental impact of production. In addition, down cotton is a highly versatile material that can be recycled and used to make a variety of products, further reducing waste.

However, the production of down cotton still has some environmental impacts. The use of solvents and additives can lead to the release of harmful chemicals into the environment, while the high temperature and pressure used in the extrusion process can lead to energy wastage. To address these issues, many manufacturers are now exploring greener alternatives and adopting more sustainable practices.

In conclusion, down cotton is a popular synthetic fiber that is made through a complex production process involving polymers, solvents, additives, water, and energy. While it has come a long way in terms of sustainability, there are still opportunities to further reduce its environmental impact. Consumers can look out for sustainable options when purchasing down cotton products to help reduce the environmental footprint of this popular material.

Articles related to the knowledge points of this article:

Feathered Jackets: A Fashion Must-Have for Winter

Title: Mastering the Art of Korean Necktie Tying: A Comprehensive Guide

High Fashion Winter Coats: The Definitive Guide to Choosing the Best One for You

Feathered Jacket 90: A Guide to Staying Warm This Winter